For the excellent practicability across a wide range of industries, it’s believed that the global stainless steel market will keep growing and finally achieve an incredible scale. One of the most impressive improvements in the industry has been the sustainability of stainless steel. To reduce carbon emissions, people have started to use scrap steel. Researches from Technavio have shown that the market will grow over 5% by 2021. As a country with great influence in the steel industry, China plays a key role in the global stainless steel market. In this article, we will share the knowledge about stainless steel and some information about stainless steel manufacturers in China.

Stainless Steel is short for Stainless acid-resisting steel. We call the steel which is resistant to air, steam, water, and other slightly corrosive mediums as Stainless steel. Besides, there is one kind of steel which can resist the chemical corrosion(acid, alkali, salt and other kinds of chemical erosion)We have named it “acid-resistant steel”

The word “stainless steel” does not refer to a certain kind of stainless steel, but includes more than one hundred kinds of industrial stainless steel.

People often develop a stainless steel for a certain application. Before choosing which kind of steel we want, we must be clear about applications. Six types of steel are relevant to the construction. They all contain 17 to 22 percent chromium, and some better types of steel also contain nickel. The addition of molybdenum can further improve the resistance to atmospheric corrosion.

In general, the hardness of stainless steel is higher than that of aluminum alloy, but the cost of stainless steel is higher than that of aluminum alloy.

We must know that stainless steel is an iron-containing alloy in the first place. People melt different kinds of raw materials like nickel,iron ore, chromium, silicon, molybdenum, and others together to make stainless steel.

Over 57 stainless steels are recognized as standard alloys, in addition to alloys produced by different stainless steel producers for different applications. Different proportions of stainless steel elements determine the type of stainless steel. The ratio of iron to other materials makes a difference to how strong the protective oxide layer is, how resistant the metal is, and a few other mechanical properties (hardness, melting point, shear modulus, etc.)

People have developed many ratios of steel components to produce different types of stainless steel alloys.

Each combination is referred to as a “grade” of stainless steel. Grade 304 stainless, grade 316 stainless, grade 201 stainless and grade 202 stainless steel are the most common products in the market.

Now we know what raw materials we need to produce stainless steel. The following content of this part will be the details of each step. Different grades of stainless steel are various in some manufacturing processes. How a grade of steel is shaped, worked, and finished has a great influence on the appearance and functions.

Almost all kinds of steel grades have the same steps at the beginning of manufacturing.

The raw materials and additives (what materials need to be used decided by the grade of steel you want to produce) will be first melted together in an electric arc furnace(EAF). With high-power electrodes, this step requires 8-12 hours to heat the metals, creating a fluid mixture. The temperature of EAF is decided by the grade of steel.

We can realize that the improvement of sustainability mentioned above. As stainless steel is recyclable, many stainless will contain 60% recycled steel at most. Which helps to control costs and reduce environmental damage.

The proper level of Carbon in stainless steel can affect the hardness and strength of iron. Too much carbon can lead to precipitation during the process of welding. That’s why we need the second step- Removing excess carbon.

The fluid mixture we have from the first step will be placed into a vacuum oxygen decarburization(VOD) or argon oxygen decarburization(AOD) system to remove excess carbon.

Different carbon content can lead to different grades of stainless steel.

After the reduction of carbon, the molten steel may be stirred to remove specific components from the mixture. Which helps to meet the standard of a certain grade of stainless steel and ensures its quality. Samples will be tested and analyzed again and again until the mixture meets the requirement of customers.

When the stainless steel begins to cool, it will go through various forming processes. When the temperature of the steel is above its crystallization temperature, manufacturers will start with hot rolling. Through hot rolling, the stainless steel is often shaped as billets or blooms. If you want metal blooms or billets with precise dimensions, cold rolling would be a better way.

Most steels need to go through a process of annealing after Forming. The annealing includes controlled heating and cooling cycles, relieving internal stress, and softening steel. The temperature and times of this step should depend on the grade of steel.

After the various steps above, the steel often accumulates scale on the surface. The scale can be harmful to the stain-resistance, durability, and weldability of the steel. Descaling is essential to creating the oxide barrier, which provides stainless steel resistance to corrosion and stain.

Cutting operations are necessary to get the desired shape or size. When the steel is ready, the batch is cut to satisfy the requirements of customers. A variety of methods can accomplish mechanical cutting, including cutting with guillotine knives, circular knives, high-speed blades, or punching with dies.

Finishing is the last step in the manufacturing process. But it’s also important to the products. Some kinds of surface finishes make stainless steel easier to clean. A smooth surface can provide better corrosion resistance. Common methods we always use for finishing include acid or sand etching, sandblasting, belt grinding, belt buffing, and belt polishing.

201 stainless steel has a resistance to acid and alkali. There are no bubbles on the surface because of the finishing. This kind of stainless steel is a good material for the watch case, water band, and so on. It can also serve as a premium material for decorative pipes, industrial pipes, and products with low elasticity.

Read our previous article about grade 201 of stainless steel:Overview of 201 stainless steel pipe

304 stainless steel is a popular type of stainless steel with a high-temperature resistance of 800 °C, which is widely used in the manufacture of equipment and components with corrosion resistance With good machinability and high toughness, the products made of 304 stainless steel always applied at the industry, furniture industry, food industry, and pharmaceuticals industry.

Read our previous article to get more information about 304 of stainless steel:

With the addition of Mo, it has excellent corrosion resistance and atmospheric corrosion resistance. It can be used in harsh environments such as high temperatures. The products made of 316 stainless steel are related to Seawater equipment, chemical, dye, paper making, oxalic acid, fertilizer, photography, food industry.

The development of the Chinese stainless steel industry is relatively late.

The demand for stainless steel in China is mainly based on the advanced use of industry and national defense.

The rapid development of the national economy and the significant improvement of people’s living standards pull up the demand for stainless steel.

China’s stainless steel industry entered a period of rapid development. At that time, the stainless steel demand growth rate was much higher than the global level.Since 1990, the global consumption of stainless steel has grown at an average annual rate of 6%, and in the first 10 years of the 1990s, the consumption of stainless steel in China was 2.9 times the world average annual growth rate. In the 21st century, China’s stainless steel industry is growing rapidly.

the average annual growth rate of China’s stainless steel consumption was more than 21.17%. In 2001, China’s consumption of stainless steel reached 2.05 million tons, exceeding the number of United States to become the world’s largest stainless steel consumption country.

Stainless steel is the most widely used steel material with the best performance and price ratio in the world. With the implementation of the western development strategy, power transmission from west to east, gas transmission from west to east, the Three Gorges Project, China’s hot-dip galvanized industry has entered a new round of high-speed development.

With the increasing competition in the stainless steel industry, mergers and acquisitions and capital operation among large stainless steel production enterprises are becoming more and more frequent. The domestic excellent stainless steel production enterprises are paying more and more attention to the research of the market, especially the in-depth study of the trend of customer demand. Because of this, a large number of domestic excellent stainless steel brands rapidly rise and gradually become the leader in the stainless steel industry!

Click here to know more about how to buy stainless steel coil from China:

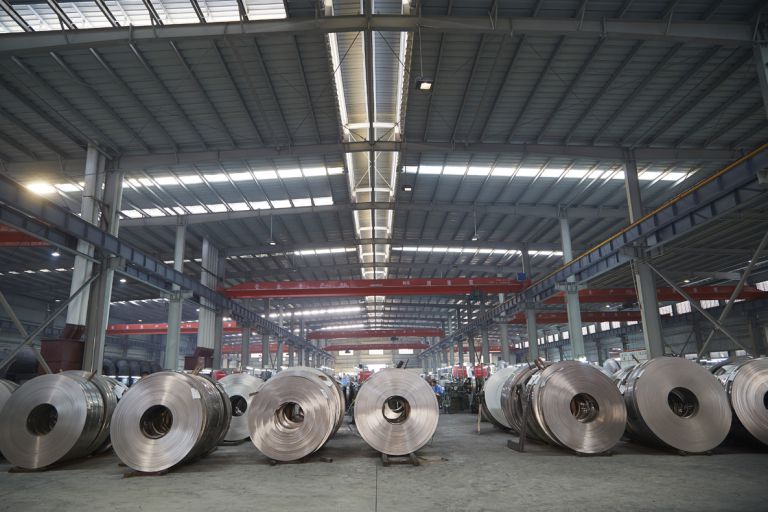

As we mentioned above, a thriving market gives a rise to many excellent stainless steel brands in China. We will take WANJIAHONG as an example

With over 24 years of brilliant achievement, Wanjiahong has been recognized as a famous brand in the Chinese stainless steel decoration business. The companies are equipped with advanced machines, such as 5 fully automatic flatten & slitting machines, 8 PVD color coating machines, 6 mirrors 8K polishing lines, 2 embossed lines, over 150 welding equipment, and 10 automatic packing machines.

Core products are stainless steel 201/304 decorative sheets, 201/304 stainless steel pipes, No.4&Hairline/Mirror 8K stainless steel coils. 47 of our embossed products are with appearance patents, and our continuous innovation still going further to meet all of your special pattern designs.

In this article, we introduced different kinds of stainless steel and the production process. Besides, you may also get an overview of China’s stainless steel market and the top-class producer.

Hope that this article can help you. If you have any other questions, try to find the answer from the previous article on this page, or lead comments to us, we will reply to you as soon as possible.

Please feel free to contact us any time using the form or other information below. Our team will respond to you quickly and will be able to answer any questions you may have.