Stainless steel originated in the early 20th century in western countries. Since the day of its birth, the stainless steel industry has been regarded as a high-tech industry.

With the overall development of science and technology in the past hundred years, the application of stainless steel, from the decisive factor contributing to the win or lose of war gradually developed into a significant factor that makes a great difference to the nuclear power plants, giant bridges, reservoir gates, and other infrastructure; Many high-tech products like cell phones, computers, cars, refrigerators, washing machines, and others, include parts of components made of stainless steel.

No matter you have interests in stainless steel products or want to step into this industry, more knowledge about stainless steel companies around the world will do you a favor in promoting the understanding.

In this article, We will introduce some stainless steel companies from different countries, including Wangjiahong stainless steel group. Krupp Thyssen Stainless Steel Company and others.

Established in 1997, Krupp Thyssen Stainless Steel Company was formed in 1995 by the merger of the German Krupp Company and Thyssen Corporation stainless steel flat steel production

Cooperated with Shanghai Pudong Iron&Steel Group, Shanghai Krupp Stainless Steel(SKS) has been founded in the same year.

At present, Krupp Thyssen Stainless steel has an annual production capacity of 1.3 million tons at AST in Italy.

Its other four main subsidiaries boast a total annual production capacity of 1.9 million tons of crude steel and a total capacity of 1.65 million tons of cold-rolled stainless steel flat, which makes Krupp Thyssen Stainless the world’s largest stainless steel producer.

Its flat products account for approximately 37% of the European market share and 15% of the world market share. Under the impact of mergers and restructuring of global steel companies, Krupp Thyssen Stainless Steel, to maintain its position as the world’s dominant stainless steel company, adopted several strategies, such as expanding production capacity, adopting advanced technologies, focusing on product mix reorganization, and improving services for customers.

AST, the 90%-owned subsidiary in Italy, is a stainless and electrical steel producer with a full process of smelting, continuous casting, hot and cold rolling. All of these have significantly increased the stainless steel production capacity of AST’s Terni plant, and the annual production capacity of stainless steel hot-rolled strip will increase to 650,000 tons, with total production expected to reach 1.5 million tons in 2003.

Also, Krupp Thyssen Stainless is seeking to build a plant in the United States or seek new partners, to ensure the supply of the entire NAFTA with the company’s subsidiary Mexican stainless steel company.

Sales in NAFTA currently account for 15 percent of Krupp Thyssen Stainless’s total sales volume. The cold rolling mill of Mexican Stainless has an annual capacity of 220,000 tons and is now supplying the United States with more than half of its production. North America is a very attractive market. Krupp Thyssen Stainless entered China three years ago with the same strategy, establishing the Shanghai Krupp Stainless joint venture with Shanghai Pudong Steel Company, which is a full process stainless steel flat steel production enterprise with an annual capacity of 500,000 tons of crude steel. The first phase of the project was put into operation in November 2001, with an annual production capacity of 72,000 tons of bright plate.

The main products of Krupp Thyssen Stainless steel are hot rolled pickled and cold rolled coils of austenitic stainless steel in various surface states, pickled hot-rolled coils of ferritic stainless steel, and cold rolled coils of austenitic stainless steel in thick sizes.

Founded in 1948, Usinor is France’s largest steel conglomerate.

In the 1980s, Usinor spent billions of dollars for plant and equipment expansion to improve itself as an important supplier of flat-rolled products for the European automotive industry and Europe’s largest stainless steel producer. After the privatization in 1995, Eugenol embarked on an ambitious program of international investment and expansion. 1997-1998 saw a series of overseas investments of Usinor in the stainless steel business. In 1998, Uchinor acquired a controlling interest in Acesita, Brazil, making it a subsidiary of Uchinor.

In 2000, Acesita reached an annual production capacity of 300,000 tons of stainless steel plate, 50% of which exported to North America and Europe.

n December 1998, Üzinor also acquired 53.5% of interests of J & L (JOBeSandLaughin) Inc. (JOBeSandLaughin), the largest stainless steel production plant in the United States in the 1980s.

Then, a merger and acquisition happened between Üzinor company and Albedo Group.

That’s why the Belgian Al (ALZ) company, which is the subsidiary of Albedo Group under the Belgian was merged into the Üzinor company.

Arcelor has established a deal for the final merger between the Üzinor company and the French Ügine SA (UgineSA)

At present, ALZ stainless steel, with an annual production of about 600,000 tons, is one of the few manufacturers in the world that can produce a 2000mm wide stainless steel plate.

Avesta Polariet is a world-class multinational stainless steel company, which is formed in September 2000 by Avesta-Sheffield and Finland’s Outokumpu (Outokumpu).

Now it has an annual stainless steel plate production capacity of about 700,000 tons. Its plate products accounted for 13% of the global market share, with sales of over 3 billion euros.

After the formation of the Avesta-Polaris, it embarked on a series of restructuring and investment in the subsidiary production plant of some countries. The investment project spent about 660 million euros. Among them, the Tornio plant in Finland built a new lab continuous casting machine (slab specifications 170mm X 800 ~ 1 650mm), with an annual output of 800,000 tons.

After the plant also built an integrated hot-rolled and cold-rolled stainless steel production line, achieving an annual processing capacity of 1.1 million tons.

The company has two smelters in Sweden and the UK,equipped with the technology of electric furnace smelting, AOD, or CLU unit refining.

Korea POSCO once was the world’s largest steel producer, with an annual production of 25.57 million tons of crude steel in 1998, replacing the Nippon Steel Corporation of Japan, which had held the world’s top crude steel production position for 30 years.

However, since the 1980s, with the development of the automobile industry, electronics industry, and other new industries, the market demand for steel products has been developing in the direction of advance, multi-species and small-lot, and POSCO has promptly adjusted its product structure, increasing the proportion of high value-added products such as stainless steel sheets and coils, coated steel sheets and automobile steel sheets year by year.

POSCO’s products have strong competitiveness in the international market, which comes from low cost, high efficiency, good quality, reasonable product structure, and adaptability to market needs. To further improve the status of its products in the world, the company has invested directly abroad, producing locally and selling locally for higher profits. By 1997 it had established 25 wholly-owned, joint ventures in the United States, China, Vietnam, Indonesia, and Thailand, with nine joint ventures or wholly-owned companies in China, including Zhangjiagang POSCO Stainless Steel Company, which was put into operation in January 1999 with an annual capacity of 110,000 tons of In October 2002.

Yelian Ltd. was established in December 1988. With its headquarter in Kaohsiung, Yelian is the largest stainless steel company in Taiwan. The main products and services are stainless steel hot rolled steel coil (plate), stainless steel cold rolled steel coil (plate), stainless steel small steel blanks, and stainless steel flat steel blanks.

It has six production plants, including steel-making plant 1, plant 2, hot rolling plant, cold rolling plant 1, plant 2, plant 3. As of 2009, the proportion of products are 27% of hot rolled stainless steel coil, 56% of cold-rolled stainless steel coil, 6% of stainless steel billets, and 10% of stainless steel flat bar billets.

The products are mainly sold domestically, accounting for more than 60%, while export sales account for more than 30%, with markets mainly in Hong Kong, Macau, China, Asia, Europe, and the United States. The main stainless steel plants in the Taiwan market have expanded their production capacity to meet the market demand, among which Yelian has a steelmaking capacity of 1 million tons, a hot rolling capacity of 950,000 tons, and a cold rolling capacity of 600,000 tons.

Wanjiahong Stainless Steel Group is a comprehensive large-scale stainless steel enterprise integrating design, R&D, production, and sales with diversified, multi-brand, and group operation

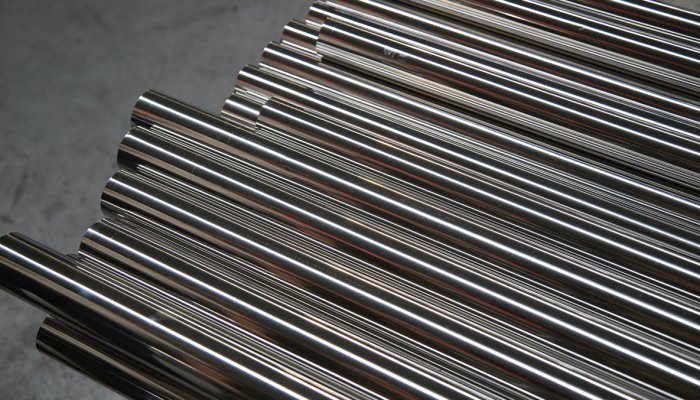

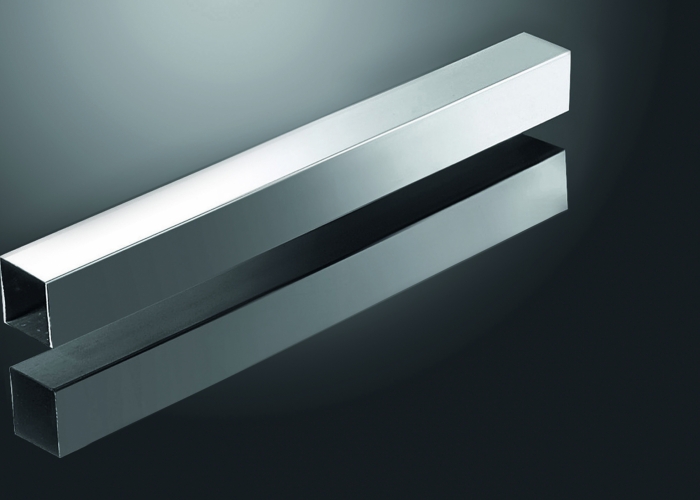

Founded in 1996, the company is located in Lanshi, Foshan, which is known as the “Stainless Steel Capital of China”. It is a comprehensive large-scale stainless steel enterprise with diversified, multi-brand and group operation, integrating design, R&D, production, and sales. It has five production bases, four famous brands (Wanjiahong, Steel Zhuo, Junganghong, Jiajianhong) and four wholly-owned subsidiaries (Foshan Steel Zhuo Steel Co. Committed to providing domestic and foreign customers with high-quality 304, 201 stainless steel, decorative plates, and decorative tubes, 300 series, 400 series, and stainless steel coil, flat, as well as high-quality aluminum profiles, aluminum alloy doors, and windows, 304 European-style tubes, steel Zhuo original plate embossed pipe, product accessories and other ancillary services products.

Wanjiahong Stainless Steel Group has been in a leading position in the Chinese stainless steel industry. With more than 1,500 employees, including more than 300 excellent managers and technical backbones, the company has a comprehensive production capacity of over 80,000 tons of pipes and 130,000 tons of plates per year

They have invested heavily in the upgrading of product quality, equipment, and technology, introducing 5 sets of world advanced and precise automatic flat slitting and leveling machines, 2 sets of embossing and drawing machines, 6 sets of color vacuum plating furnaces, more than 150 sets of pipe welding equipment and 10 sets of automatic packaging machines, and other high-performance processing equipment.

China Baowu Steel Group is the largest and most modern steel conglomerate in China.

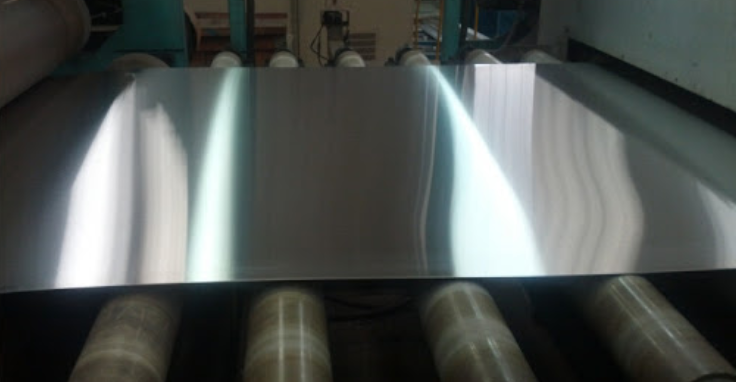

With the characteristics of large-scale, continuous and automatic, all the equipment and technology Baosteel uses are built on advanced technology including contemporary steel smelting, hot and cold processing, hydraulic sensing, electronic control, computer and information communication, and others.

Through continuous technical improvement, it maintains the leading position in the technology level among stainless steel manufacturers around the world.

The company adopts international advanced quality management, and its main products have been approved by international authorities. It has passed the ISO9001 certification and review of BSI British Standards Institute. It has been awarded the American API certificate and Japanese JIS approval certificate.

It has gotten the QS 9001 conformity certification of the world’s three most famous automobile factories, such as General Motors, Ford, and Chrysler, and been approved by seven national classification societies, such as China, France, the United States, Britain, Germany, Norway, and Italy.

With strong R&D strength, The company is engaged in the development and research of new technologies, new products, new processes, and new equipment, which has accumulated inexhaustible development momentum for the company.

The company attaches importance to environmental protection and pursues sustainable development. It is the first company in China’s metallurgical industry to pass the ISO14001 environmental compliance certification, which is known as the most environment-protecting steel enterprise in the world.

In the list above, we can see both the well-known titans like the China BaoWu steel group and rising ones like Wanjiahong stainless steel group. Stainless steel is a material we can not live without. There is no doubt that the stainless steel market will have a bright future. More and more people will try to involve in the business.

Hope this article can help. If you have other questions, feel free to contact us through email, we will reply as soon as possible.

Please feel free to contact us any time using the form or other information below. Our team will respond to you quickly and will be able to answer any questions you may have.