Conclusion

201 stainless steel plate is a low-nickel stainless steel plate. Moreover, it is a high-strength hardened austenitic stainless steel.

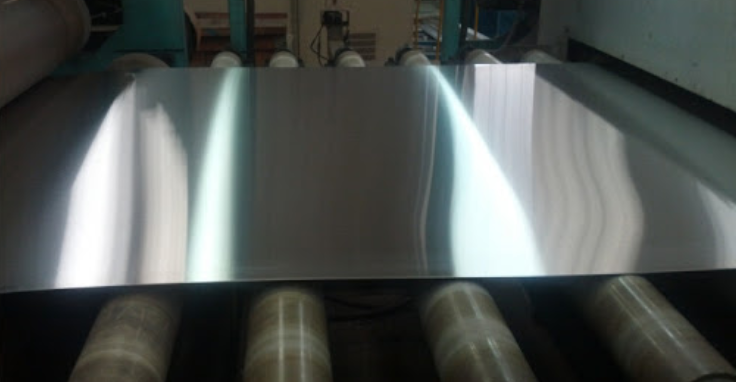

People use chromite, iron ore, manganese, nickel, and other raw materials extracted from underground mines to make slabs. Then, after hot rolling and cold rolling, 201 stainless steel plate is made.

After that, there are different processes according to different purposes and uses.

And including water plating processing technology, vacuum evaporation, electrophoresis technology.

As for its properties, its bend-ability, form-ability, and tensile properties are similar to those of Type 301.

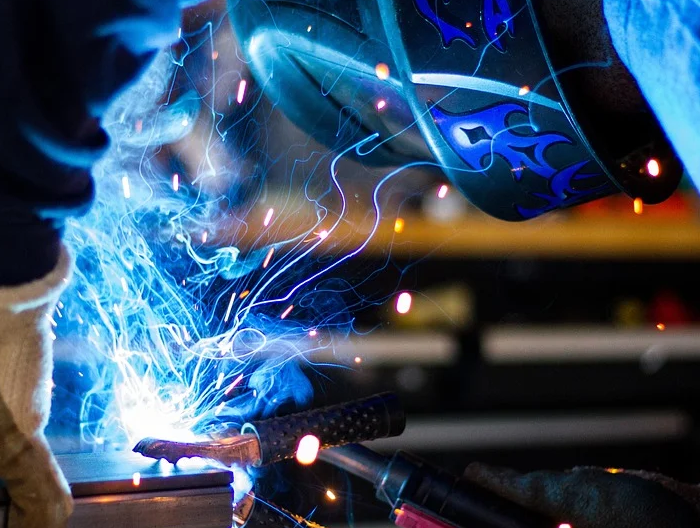

Moreover, people can weld 201 stainless steel plates to 18% chromium and 8% nickel steel by all conventional methods. Meanwhile, in mild to moderately corrosive environments, 201 has corrosion resistance.

However, it also has its disadvantages.

For example, its corrosion resistance is not as good as other similar stainless steels.

Moreover, its durability is not as good as Type 304.

During the production and recycling process, people cannot trace their materials.

However, with the development of the stainless steel industry, there are many types of 201 stainless steel plates:

- Stainless steel wire drawing board

- Mirror stainless steel plate

- Stainless steel coated steel plate

- Microporous sound-absorbing board

- Stainless steel checkered plate

- Titanium mirror panel

- Color profiled steel plate

As for its application, the 201 stainless steel plate is very suitable for high-temperature applications.

That’s all for the 201 stainless steel sheet today.

If this article is helpful, please share it with your friends.