Conclusion

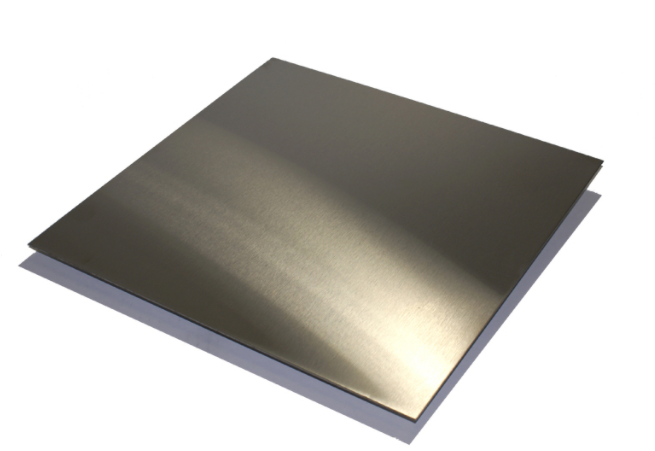

304 stainless steel sheet is austenitic stainless steel.

Moreover, it is non-magnetic.

Therefore, even after welding, people do not need to return it.

There is chromium nickel in the 304 stainless steel sheet. Moreover, there is still a small amount of carbon in it.

Therefore, it has high corrosion resistance.

At the same time, it is very durable.

And when making 304 stainless steel sheets, people usually follow these steps: heating, rolling, pickling, inspection, finishing, and cutting.

As for its properties, its corrosion resistance and high temperature oxidation resistance are very good.

Moreover, people can weld or process it.

In addition, it can maintain a neat and beautiful appearance.

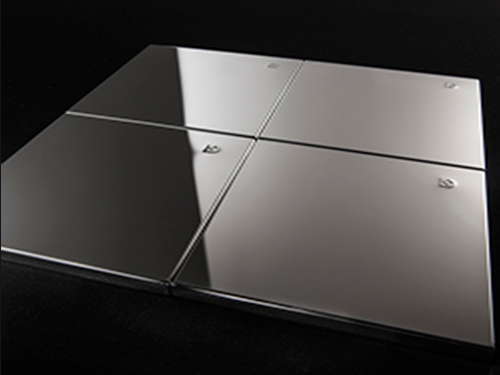

On the 304 stainless steel sheet, people can perform many surface treatments.

For example, No. 4 surface, No. 8 mirror, 2B type surface.

In addition, people can compose it into energy-saving and environmentally-friendly composite board materials.

Because of its good performance and low cost, it is already one of the most widely used stainless steels.

At last, if you like this artcle, please share it with friends.