Nowadays,we can see products made of stainless steel anywhere. These products cover the areas from construction to daily necessities. A variety of uses promises considerable China and overseas markets. As a country with great power in the export business, China deserves our attention, especially the stainless steel area. In this article, we will analyze both global and Chinese markets. Also, we will provide some information about Chinese Stainless Steel Suppliers, and the difficulty they are facing.

With chemical corrosion resistance, stainless steel is Stainless acid-resisting steel for short. Such resistance enables stainless steel to avoid the corrosion of air, water, steam, and so on.

What’s more, stainless steel is one kind of alloy. For the different proportions of raw materials, different kinds of stainless steel boast unique properties. Therefore, people classify stainless steel in terms of its compositions, including chromium stainless steel, chromium-nickel stainless steel, chromium manganese nitrogen stainless steel.

Due to the different use of each product, its processing technology and requirements for raw materials are also different.

People use stainless steel to produce equipment for fields like construction, hospital, elevator, food processing and chemical, brewing, catering industry, etc.

In some certain fields like brewing and catering, it’s necessary to clean the equipment daily. Sometimes a cleaning agent is needed because it’s easy to breed bacteria.

With the continuous development of technology, the coloring technology of stainless steel has achieved a breakthrough.

The process of “cold rolling – coloring” shorten the production effectively, thus improving the production efficiency of color steel. Besides, this kind of process achieves the integration between steel production and coloring, satisfying the demands of different customers.

Read our previous articles to know more about different kinds of stainless steel

The workpiece is heated to a predetermined temperature and then held for a certain time and then cooled down slowly. The purpose of annealing is to:

A. eliminate the defects and residual stress caused by the casting, forging, rolling, and welding process. In such doing, we can prevent the steel from deformation and cracking.

B. soften the steel for cutting.

C. refine the grain to improve the mechanical properties of the steel.

D. Prepare for the final heat treatment and pipe production

In this step, people roll and cut the stainless steel plate into the corresponding width, to carry out further processing.

The slitting process should pay attention to prevent the surface from scratching caused by the slitting knife.

Besides, the slitting cloak and burr are of vital importance to the pipe-making process.

Most important step for producing stainless steel pipe. Argon arc welding and plasma welding are the main ways people use to make stainless steel pipes.

Argon arc welding shield gas is pure argon gas, mainly welding stainless steel pipe below 3mm, plasma welding has a strong penetration, mainly welding 5-8mm stainless steel pipe.

Most important step for producing stainless steel pipe. Argon arc welding and plasma welding are the main ways people use to make stainless steel pipes.

Argon arc welding shield gas is pure argon gas, mainly welding stainless steel pipe below 3mm, plasma welding has a strong penetration, mainly welding 5-8mm stainless steel pipe.

During the process of wielding, we need to polish the weld bead and cool it down with water.

After the water-cooling, use a water mill to grind the weld bead until the surface is smooth.

The process of stainless steel welded pipe is called Extrusion Production. All square tubes and rectangular tubes are originally made of round tubes.

A. Producing the same round tubes with the same perimeter

B. Extruding them into the corresponding square tubes and rectangular tubes

C. Using molds to reshape and straighten.

The cutting process of the stainless steel tube is relatively rough, and most of them are cut by a grinding wheel. Cloaks will be produced after cutting, which need to be further trimmed. The other way of cutting is the band saw cutting, which has relatively good accuracy.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

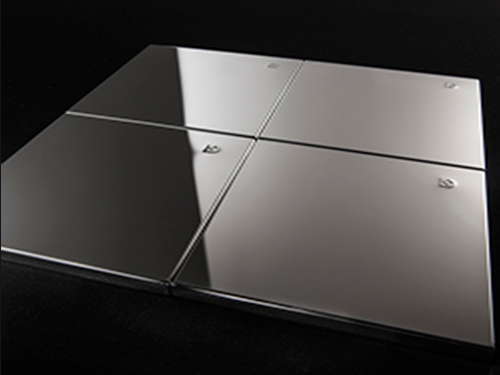

Generally, there are several processes for surface treatment

These processes can be divided into 400#, 600#, and 800#, which are respectively suitable for different levels of customers

This step mainly is for checking whether the outer diameter and thickness, surface treatment, and welding process are up to the standard.

Early in the 1990S, the United States, Europe, Japan, and other developed countries had achieved basic popularity of stainless steel water pipes, stainless steel gas pipes. Buildings in coastal, wet areas are mostly constructed by stainless steel rebar, wire, and other new materials with corrosion resistance.

With the continuous improvement of life quality, the application of stainless steel in life continues to increase, there is a huge market for stainless steel, both in China and abroad.

Researches shown that India’s per capita apparent consumption of stainless steel is less than 2 kg, Indonesia’s per capita apparent consumption is only 0.6 kg. These numbers are far lower than the global average of 5.5 kg. Which means a huge market potential.

With a poor economic development, Asia-Pacific regions surrounding China, as well as Africa, Latin America, and other developing economies have an insufficient production capacity of stainless steel, providing China’s a broad overseas market.

In 2019, China’s stainless steel production is 29.4 million tons, a 10.1% increase over the previous year, 26.706 million tons. China’s stainless steel supply accounts for 56.30% of the global proportion.

In the ratio of stainless steel production and supply, China accounts for more than 50%, of which Europe accounts for 13%, the United States 5%. From the perspective of domestic demand, the domestic demand for stainless steel in 2011 achieves 10,000 tons. To 2019, China’s stainless steel demand had climbed to nearly 30 million tons.

In China, subject to traditional thoughts, people think that stainless steel is expensive. Stainless steel has not been used at a large scale and largest area. Along China’s 18,000-kilometer-long coastline, tens of millions of ships, houses, and Bridges suffer daily erosion from seawater, salty moisture, and so on. Traditional carbon steel building materials are difficult to resist corrosion damage.

That’s where the demands show up, we need a lot of stainless steel to upgrade these buildings.

The stainless steel market is going to be mature. As the prices of chromium, nickel, and other raw materials run low, stainless steel prices have only a fifth of the historical highest price.

However, because of the consumption concept, some people think that using stainless steel is a luxury idea, which is not economical.

They did not take into account the different marginal costs of these two materials, which limits the use of stainless steel.

With the wider popularity of stainless steel in the future, it’s believed that the price can be reasonable gradually and so does the consumption view.

The demand for stainless steel in China will have exploration in the future. Together with the potential market overseas, there is no doubt that the stainless steel industry boasts a bright future.

The stainless steel industry has three barriers, which makes it harder for enterprises without any relative experience These three barriers mainly reflect in the following three aspects:

(1) Policy Barriers: The iron and steel industry is currently a key target of national regulation and control. There are strict restrictions on projects with excess capacity, backward technology, and serious environmental pollution. This barrier raises the threshold for entering the steel industry.

(2) Technical barriers: stainless steel production involves many technical links and complex processes. The production and development of high quality and high value-added stainless steel products not only need capital and personnel investment but also need the accumulation of production experience.

(3) certification barriers: stainless steel rods and wires are mainly used in the key parts of the equipment manufacturing field. End users have high requirements for product quality and stability. It is necessary to ensure the reliability and stability of product quality through the form of supplier certification. That’s the third reason why the new suppliers are hard to enter the industry.

The concentration degree of the stainless steel industry is higher, and the output of long-material production enterprises is lower.

Stainless steel production enterprises with high output are mostly plate products, which account for up to 90% of the output. Long material production enterprises are not high in output. The main reason is that long material specifications are many, and the precision of products is higher, so the production cycle is long and the production capacity is low.

Because of Multiple specifications and requirement for fineness, companies producing long material products have a low output and a long production cycle

With a high density of stainless steel, most of the products from high-yield companies are sheet material, which accounting 90% of the whole output.

In terms of China’s region, East China boasts a booming economy and complete industrial categories. The consumption of stainless steel keeps pace with that of South China.

At the same time, East China has many stainless steel processing and clusters.

Different stainless steel industry clusters have certain characteristics. The consumption of stainless steel in East China varies among provinces and cities.

The development of the downstream industry is quite balanced, and the total consumption of stainless steel accounts for about 40% of the total apparent consumption in China.

Though the difficulties we mentioned above can be frustrated. Many entrepreneurs make up their minds to step into the stainless steel industry. Therefore, great deals of stainless steel enterprises have risen in Foshan. That’s why Foshan is the most representative market in South China. It is a national trade center mainly for civilian use.

Though Chinese Stainless Steel Suppliers have a complete range of varieties and specifications, they still need to invest more in technology innovation and applications. Besides, with an increasing appeal to environmental protection, many higher-level demands have been raised by customers, especially the high-end customers. Which is another power for the suppliers to improve the technology.

Through this article, you may get some information about stainless steel, including:

What Is Stainless Steel ?

How to make stainless steel?

Besides, you may also have a clear knowledge about the circumstance of Chinese stainless steel:

Global Stainless Steel Market

The difficulty of Chinese Stainless Steel Suppliers

Chinese Stainless Steel Suppliers

If you have other questions, send an e-mail or leave a comment. We will reply as soon as possible. Thanks for your reading.

Please feel free to contact us any time using the form or other information below. Our team will respond to you quickly and will be able to answer any questions you may have.